In the world of industrial operations, the design of a crusher plant layout plays a crucial role in optimizing the efficiency and productivity of the facility. The Philippines, known for its thriving mining and quarrying industries, presents a unique context where careful consideration must be given to various factors to ensure the effectiveness of a crusher plant. This article will delve into the key aspects involved in designing a crusher plant layout tailored specifically for the Philippines.

Factors to Consider When Designing a Crusher Plant Layout

When embarking on the design of a crusher plant layout, it is essential to carefully assess the site where the facility will be established. Geographical considerations, such as the topography and geological characteristics of the location, must be taken into account. Additionally, ensuring proper accessibility and transportation infrastructure is vital to facilitate the movement of materials and equipment required for the plant’s operation.

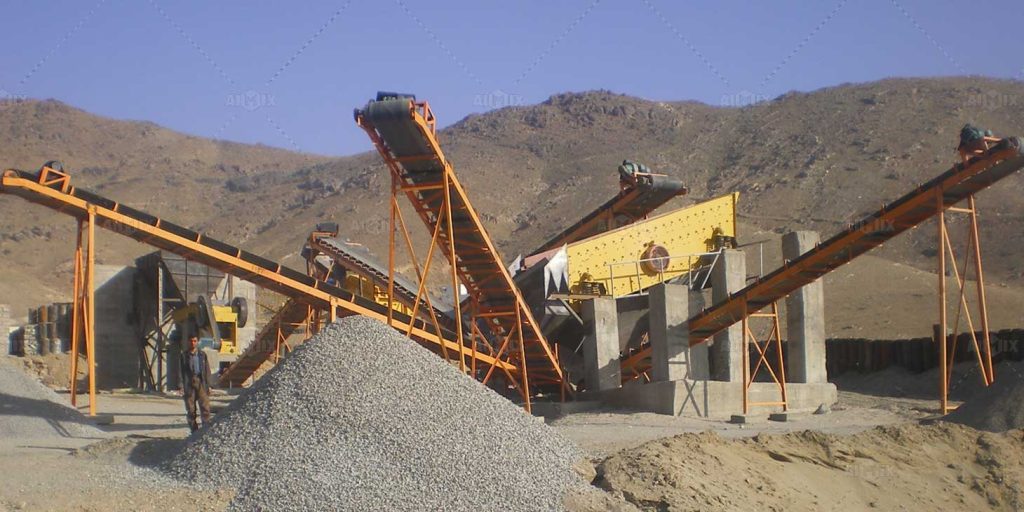

The selection and arrangement of equipment within a crusher plant have a significant impact on its overall performance. Various types of crushers are available, each suited for specific materials and production requirements. It is crucial to select the appropriate stone crushers for sale that can effectively handle the anticipated workload. Furthermore, optimizing the positioning of equipment within the layout is essential to minimize material handling and streamline the operational flow.

Steps to Design an Efficient Crusher Plant Layout

To design a crusher plant layout that meets the production goals, it is crucial to conduct a thorough assessment of the specific requirements. Determining the required capacity of the plant is a fundamental step, as it dictates the size and number of crushers needed. Additionally, analyzing the characteristics of the materials to be processed, such as hardness and moisture content, enables the selection of appropriate equipment and ensures efficient operation.

The primary crushing stage sets the foundation for the entire mobile crushing and screening plant layout. Selecting the appropriate primary crusher is critical in achieving optimal results. Factors such as material type, feed size, and desired product specifications play a pivotal role in this selection process. Moreover, setting the primary crusher’s parameters, including the closed-side setting (CSS) and the stroke length, must be carefully calibrated to maximize performance.

Beyond the primary crushing stage, a well-designed crusher plant layout should consider the secondary and tertiary crushing stages. These subsequent stages aim to further reduce the size of the material and refine the product. Selecting suitable secondary and tertiary crushers that complement the primary crusher is crucial. Additionally, establishing a clear sequence of operations ensures the efficient flow of materials through the various crushing stages.

Optimizing the Crusher Plant Layout

Safety should be a paramount concern when designing a crusher plant layout. Adequate ventilation and dust control measures must be integrated into the layout to protect the workers’ health and prevent environmental contamination. Implementing safety protocols and providing appropriate safety equipment further enhance the overall safety of the facility. Learn more about crusher machine info: https://aimixgroup.ph/crusher-machine-sale/

Efficiency is key to achieving optimal productivity in a crusher plant. Minimizing material handling, such as reducing unnecessary transportation of materials between crushers, can significantly improve operational efficiency. Streamlining maintenance procedures, including regular inspections and implementing predictive maintenance techniques, helps minimize downtime and ensures smooth operation.

Conclusion

Designing a well-thought-out crusher plant layout is a critical step in optimizing the efficiency and productivity of a facility in the Philippines’ context. By considering factors such as site selection, equipment arrangement, production requirements, and safety considerations, one can create a layout that maximizes the potential of the crusher plant. With proper design and implementation, the crusher plant in the Philippines can become a cornerstone for successful mining and quarrying operations in the Philippines.