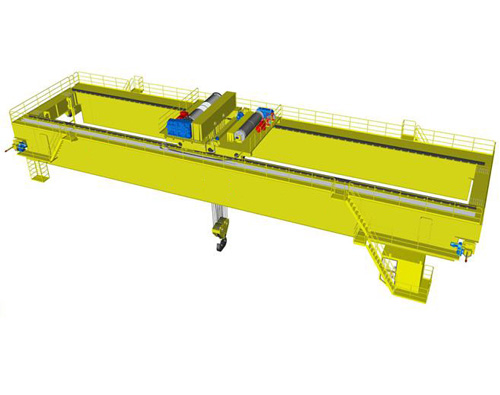

A 50 ton overhead crane is used for lifting extremely heavy weights. Therefore, it is important for you to have a maintenance plan in place in order to ensure safety, improve utilization of the crane and prolong the service life of this heavy machine. As far as the maintenance of a 50 ton overhead crane is concerned, it is recommended to have a daily, weekly, monthly, half yearly and annual maintenance plan in place.

When it comes to daily maintenance, it is important to check the important parts of the 50 ton overhead crane to make sure that no serious issues develop over a period of time. For instance, the fastening bolts should be fastened on a daily basis. Similarly, wiring of the electrical equipment should be checked to make sure that everything is fine.

The rotation mechanism of the crane should not make any abnormal sound. The weekly inspection should check for any signs of corrosion as well as wear of the brake friction disk. The maintenance person should also check the lifting mechanism along with reliability of the electrical limit switches.

A comprehensive inspection should be done at the end of each week and each month to make sure that there are no serious issues. During the monthly inspection, the lubrication of rotating shaft should be checked along with wear and lubrication of the steel wire rope. During the half yearly maintenance run, the operator and the maintenance person should work together. During this inspection period, installation of all the electrical equipment should be checked along with condition of open welding and any deformations in the metal structure.

One of the most important parts of maintenance is lubrication of the crane. It not only affects the service life but also the safety and efficiency of crane. Therefore, all the lubricating points should be clearly checked and if needed, replenishment and replacement should be done on time. As far as lubrication is concerned, all the mechanical parts that have any friction surface need to be lubricated on a regular basis. The lubrication frequency will also depend on the utilization rate as well as use environment of the crane.

It is important to have a designated personnel to perform the required maintenance and repairs. Daily inspections should be done by the crane operator before as well as after each use. The regulations also require a safety check to be done before the start of work every single time. The crane operator should be properly trained and it is duty of the operator to make sure that the equipment is ready for use before beginning operations. It is also recommended to have the operators sign a daily inspection chart before starting to make sure that safety inspection is complete.

Overall, it is important for you to keep in mind that more than 70 fatal accidents occur every year due to lack of proper maintenance and failure to follow the laid down safety inspection processes. When you work with big machinery, you need to place special emphasis on safety. It is important to take precautions when operating an overhead crane as even a slight problem can lead to fatal accidents. Keep the above mentioned tips in mind in order to create your own maintenance plan for safe operation of a 50 ton overhead crane. Know more via https://www.ellsenoverheadcraneservice.com/