Mooring winches play a pivotal role in marine operations, facilitating the safe docking, anchoring, and maneuvering of ships and offshore structures. These powerful machines are critical for ensuring the safety of vessels and personnel, making it essential to understand their operation and control mechanisms thoroughly. In this article, we delve into the intricacies of mooring winches, exploring their operation and control systems in-depth.

The Significance of Mooring Winches

Before we dive into the operation and control aspects, let’s appreciate the significance of mooring winches in the maritime industry. Mooring winches are employed for various tasks, including:

Ship Docking and Berthing: Mooring winches are vital for securing ships to docks or piers, preventing them from drifting away due to tidal currents, wind, or waves. They ensure that vessels remain in a stable position during loading and unloading operations.

Anchoring: Mooring winches are used to drop and retrieve anchors, allowing ships to stay in place when not berthed at a port. Anchoring is crucial for offshore operations, such as oil drilling platforms or research vessels.

Towing and Maneuvering: In towing operations, mooring winches are used to control the movement of vessels, assisting in navigation and docking. This is particularly important for tugboats and salvage operations.

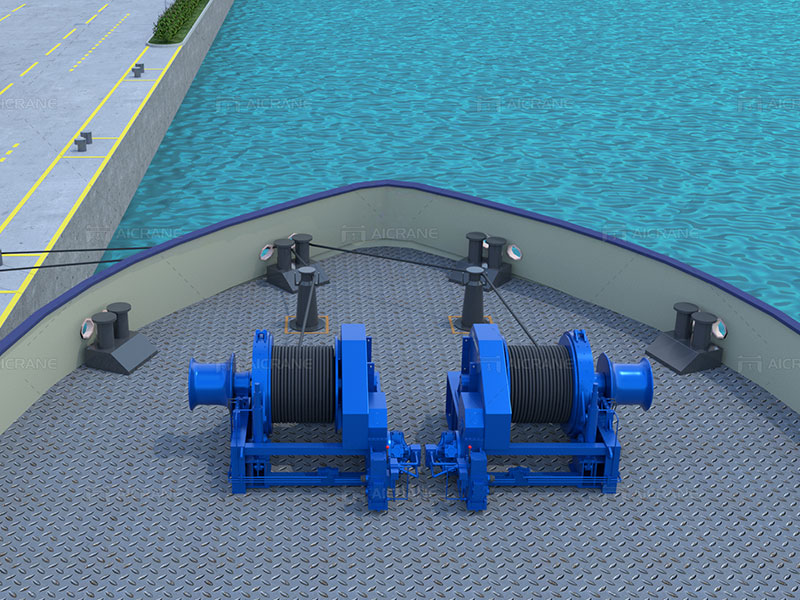

Components of a Mooring Winch

Understanding how mooring winches operate begins with familiarizing oneself with their key components:

Drum: The drum is the central component of a mooring winch and is responsible for winding and unwinding the mooring lines or cables. It provides the necessary grip to hold and release the lines as needed.

Motor: The winch motor provides the power required for drum rotation. The type of motor (e.g., hydraulic, electric) depends on the winch’s design and application.

Brake: A brake system is essential to control the release and tension of the mooring lines. It ensures that the lines can be held securely or released gradually, preventing sudden and potentially dangerous movements.

Control System: Mooring winches come equipped with control systems that allow operators to manage the winch’s functions. These controls may include levers, buttons, or digital interfaces for precise and safe operation.

Safety Features: Various safety features are incorporated into mooring winches to protect personnel and equipment. These features include emergency stop buttons, overload protection, and safety interlocks.

Operation of Mooring Winches

Mooring winches are operated with precision to ensure safe and efficient marine operations. Here’s an overview of the operation process:

Preparation: Before operation, operators need to inspect the electric mooring winch, ensuring that all components are in proper working condition. This includes checking the mooring lines, drum, motor, and brakes.

Line Deployment: When deploying mooring lines, the operator releases the brake, allowing the drum to rotate. The mooring line is guided onto the drum by winch personnel. Care must be taken to maintain even tension on the line to prevent snags or tangles.

Line Retrieval: To retrieve the mooring lines, the brake is engaged, and the winch drum starts to wind in the lines. Operators must coordinate this process carefully, especially when working with multiple lines simultaneously.

Tension Control: Mooring winches allow operators to adjust the tension on the lines. This is crucial for maintaining the stability of the vessel or structure. Tension control is typically achieved through the control system, which adjusts the motor speed and brake pressure.

Emergency Procedures: In case of emergencies or unexpected events, mooring winches are equipped with emergency stop buttons or switches. These must be used to halt winch operation immediately to prevent accidents.

Control Systems and Automation

Modern mooring winches often feature advanced control systems and automation for enhanced safety and efficiency. These systems include:

Remote Control: Some mooring winches can be operated remotely, allowing operators to control winch functions from a safe distance. This is especially valuable in hazardous or inaccessible locations.

Load Monitoring: Load sensors and monitoring systems are integrated into mooring winches to prevent overloading. These systems automatically adjust the winch’s operation to ensure that the load remains within safe limits.

Digital Interfaces: Many mooring winches now have digital interfaces that provide operators with real-time data on line tension, drum rotation speed, and other critical parameters. This information aids in precise control.

Automation: Some mooring winches are equipped with automation features that can execute predefined sequences of operations. This reduces the need for constant manual control and minimizes the risk of human error.

Maintenance and Safety Considerations

Proper maintenance is essential for the safe and reliable operation of hydraulic mooring winches. Routine inspections, lubrication, and component testing are necessary to identify and address potential issues promptly. Additionally, operators must adhere to safety protocols and receive proper training to ensure safe mooring winch operation.

Conclusion

Mooring winches are indispensable tools in marine operations, serving as the linchpin for the safe and efficient handling of vessels and offshore structures. Understanding their components, operation, and control systems is paramount for ensuring the success of maritime endeavors. With the incorporation of advanced technology and safety features, mooring winches continue to evolve, promising even safer and more efficient marine operations in the future.